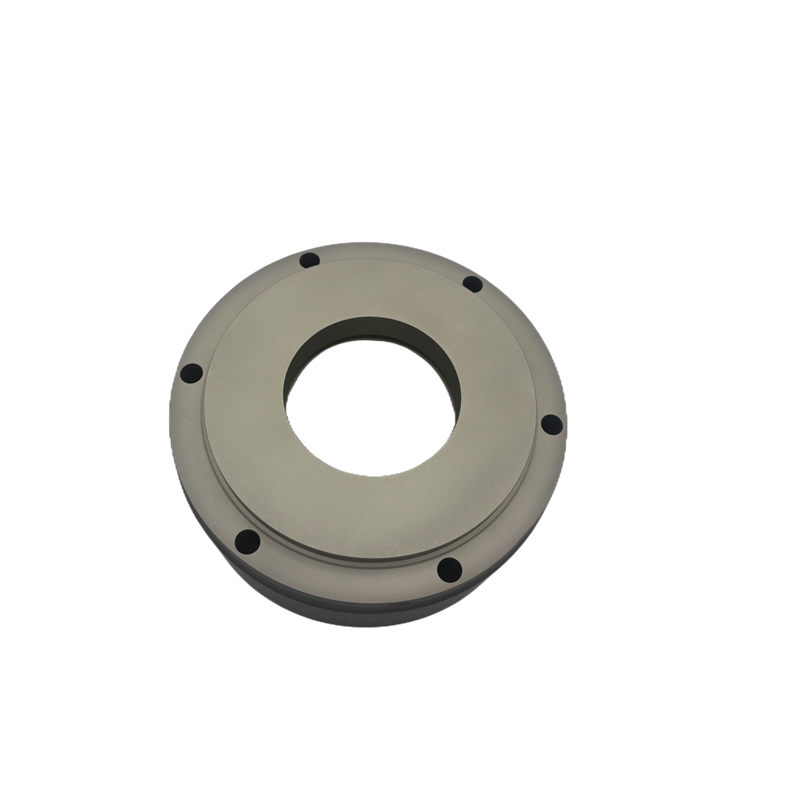

Light Base

CNC turned parts

Our CNC lathes enable high speed and high-quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for one-off prototypes through to low-volume production of your product and parts.

CNC Milled Parts

CNC milling is used to apply a machined surface finish on plastic or metal or for creating complex 3D shapes. We use domestic and imported 3, 4 and 5-axis CNC machining centers with quick-change tooling, programmed using advanced software.

Technial Parameters

Services | CNC Turning, CNC Milling, Laser Cutting, Bending, Spaning, Wire Cutting,3D Printing Servive |

Raw Material | Aluminum: 2000 series,6000 series,7075,5052 etc |

Stainlesss steel: SUS303,SUS304,SS316,SS316L,17-4PH etc | |

Steel: 1214L/1215/1045/4140/SCM440/40CrMo etc | |

Brass: 260, C360,H59,H60,H62,H63,H65,H68,H70,Bronze,Copper | |

Plastic: Acetal/POM/PA/Nylon/PC/PMMA PVC/PU/Acrylic/ABS/PTFE/PEEK etc | |

Work Table Size | 1200* 800* 500mm |

Surface Treatment | Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickl /Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc |

Surface Roughness | Min Ra 0.2~3.2 |

File Format | IGS, STP, X-T |

Tolerance | 士 0.01mm (it depends) |

Software | ProE, Solidwork, UG, 3D Max |

Surface Treatment | Including sanding, sandblasting, mirror polishing, painting, printing, laser etching, anodizing, electroplating, chroming, powder coating, etc. |

MOQ | 1 PCS |

Lead Time | 3-5 Days |

Packaging | Carton Box Or Wooden Case |

Payment Terms | T/T |